Procedure definition for the optimized design of cranial prostheses

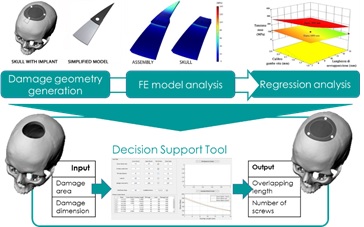

The research activities of UO3 are presented in the figure below.

Starting from an extensive bibliographic research, including international product standards, this study focused on the analysis of a clinical case of a patient with a skull damage. This pathology requires the construction of a custom-made prosthesis that meets the anatomical, biological, functional and surgical compatibility requirements with further aesthetic requirements.

Three types of Titanium alloys (Ti-Gr2, Ti-Gr5 and Ti-Gr23) have been chosen to build prostheses, because of their biocompatibility and mechanical reliability.

For the aim of this research, a polimeric skull model has been used. It is identical to a human skull, from an anatomical point of view, and its outer surface was covered of a suitable radiopac varnish for subsequent diagnostic investigations (RX, TAC). As shown in the figure, a part of the skull, from the front-apical side, has been removed to simulate the defect.

The damaged skull was analysed through TAC at the Galeazzi Institute of Milan. The machine was set using the same parameters used for clinical patient investigations. The acquired diagnostic images were then imported into an image management software (MIMICS) and a three-dimensional virtual model of the skull was developed. The final geometry of the prosthesis (upper surface to fill the bone defect) was designed using mirroring techniques

Starting from that geometry, the UO has developed a Decision Support Tool to help the surgeon for choosing the best anchoring system, taking into account the size and position of the damage. The decision support tool, as summarized in the following figure, was created using numeric data generated by Finite Element Model (FEM). This led to identify the polynomial prediction model to quantify the tensional state on the bone subjected to static load. The tool allows to define the size of the prosthesis (how much should be extended considering the defect outline) and the caliber of the stem of the screws to be used, when the area of the defect and some further clinical constraints are known.